TSM specializes in providing contract professional and technical services for commercial businesses and government contractors. This includes strategy and operations management, consulting, contract venturing/teaming, interim and project management, and related decision analytics services.

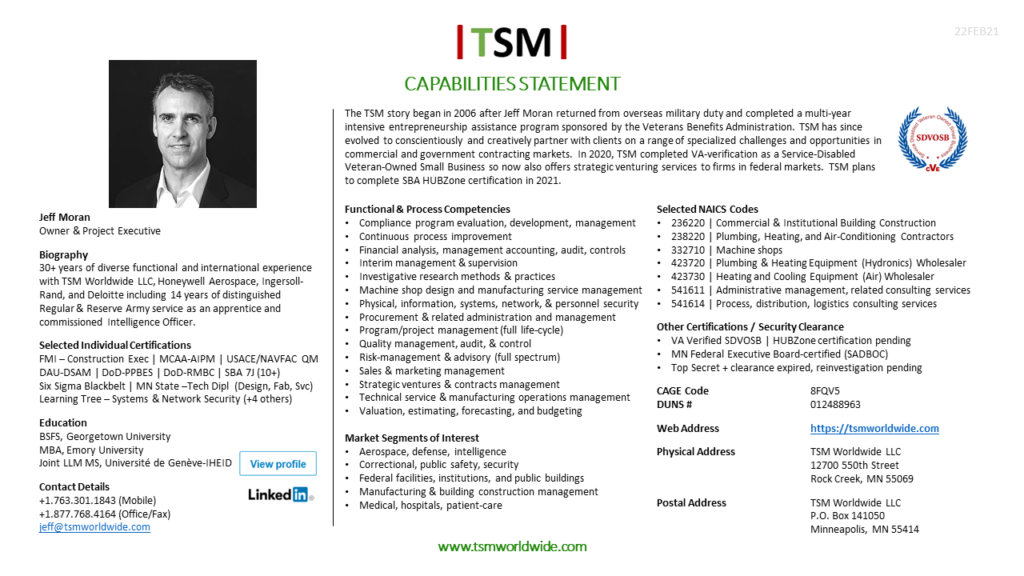

Interested partners can read our capabilities statement by clicking the image below. The capabilities statement provides an overview of competencies, markets of interest, NAICS codes, and other key details about TSM and it’s veteran founder.

A selection of recent project deliverables can also be found here. The supplemental building construction and precision machining related information below is meant to complement the capabilities statement and deliverables referenced above.

Building Construction-related

- TSM served a leading national mechanical contracting firm as partner to plan and execute strategic federal contracting business development initiatives and related programs, policies and procedures.

- Phase 1 entailed planning and executing a diagnostic assessment. The assessment concluded after several months of documentary research and dozens of interviews with internal and external stakeholders and subject matter experts. Final analysis and recommendations focused on 8 dimensions of federal regulatory/compliance program development. The CEO and COO accepted all recommendations, leading to Phase 2.

- Phase 2 entailed formation of a strategic program development initiative lead by the COO which includes two regional VP/GMs, the VP for Human Capital, and General Counsel. TSM was retained to assist in internal policy and federal strategy & operations improvement.

- TSM advised and assisted, evaluated, and developed commercial and government construction project operations improvement methods and tools for a leading national mechanical contracting firm.

- Two key projects analyzed were a new construction project involving a multiple building US Air Force hangar complex totaling over 400,000 SF and a multiple building university campus piping and mechanical room upgrade and installation of hot water systems and heat exchangers.

- Provided input on improvement process methodology and planning deliverables, led related training for strategic business project team members, facilitated multiple Six Sigma process analysis exercises for process sub team leads, and conducted critical path analysis and advisory for executives sponsors on requirements and methodology to calculate net impact and return on resources spent for construction-oriented project execution-related improvements.

Contract Precision Manufacturing-related

- TSM advised and assists an established industry partner with managerial and technical services for contract precision machining in the advanced manufacturing space. This included researching, capability building, and planning in aerospace- and defense-related market segments. TSM provided diagnostic and preparatory assistance for delivery of high-specification components in the following functional areas:

- Regulatory and compliance;

- Sales and marketing and business development;

- Contracting management;

- Strategic venturing/teaming; and

- Shop-level contract-specific operations quality and security controls.

- TSM previously advised and assisted leading consumer small arms-related advanced manufacturing specialty firms with production and assembly operations management and turn-key contract marketing, customer management, and sales services related to planning and execution of product line extensions. This work entailed:

- End-user product and market research and concept testing;

- Product design and value-proposition development;

- Component and service partner sourcing strategy;

- Requirement and specifications for contract machine shop operations;

- Printed and online video marketing materials;

- Commercial sales and buyer qualification and selection; and

- Distribution channel controls development, implementation, and management.